Sandvik Brazing System

Sandvik Brazing System in Pune

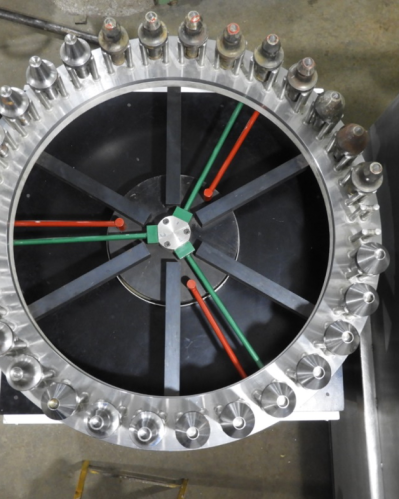

Sandvik Brazing System in Pune. This brazing system is specially manufactured for Sandvik Asia Pvt. Ltd. which is located in Pune, India. The requirement is to apply the brazing operation to their mining tools and instant cooling down.

Therefore two conveyors are provided in the system. In the first station, mining tools are placed manually, and after brazing, tools are transferred to the container which contains water at a very low temperature by using copper piping inside the container.

This transfer of tools is performed by an automated pneumatic arm. The whole system is totally automated and CNC programmed. We can provide such kind of fully automated conveyors as per clients’ requirement.

Sandvik Brazing System is a state-of-the-art technology used in Pune for the brazing of materials. Which involves joining two metal components using a filler metal. Brazing is a widely used technique in the manufacturing industry. As it provides a high-quality bond between the components, and it is also cost-effective.

Sandvik is a leading manufacturer of brazing systems in Pune. The Sandvik Brazing System is an advanced technology that is used in the manufacturing of complex parts that require high accuracy and precision. The mechanism is meant to result in a solid binding between the parts. With minimal distortion or damage to the materials. Sandvik Brazing System is widely used in the aerospace, automotive, and medical industries in Pune.

The Sandvik Brazing System uses advanced techniques such as induction brazing, torch brazing, and resistance brazing to achieve high-quality bonds between components. Induction brazing is a method of heating the material by placing it in a magnetic field, and it is widely used in Pune for the brazing of metals. Torch brazing is a technique in which a flame is used to heat the metal components. It is commonly used for the brazing of copper and brass components. Resistance brazing is a method that involves passing an electric current. Through the components to generate heat. It is commonly used for the brazing of small components.

Sandvik Brazing System in Pune provides a wide range of benefits to the manufacturing industry. The system provides high-quality bonds between components, which increases the overall strength of the product. The Sandvik Brazing System is also cost-effective, as it reduces the number of rejects and rework, which in turn reduces the overall manufacturing cost. The system is also environmentally friendly, as it produces minimal waste and emissions.

Sandvik Brazing System in Pune is widely used in the aerospace industry for manufacturing complex components such as turbine blades, heat exchangers, and fuel injectors. The system is also used in the automotive industry for manufacturing components. In the medical industry, Sandvik Brazing System is used for manufacturing medical devices. Such as surgical instruments, implants, and dental equipment.