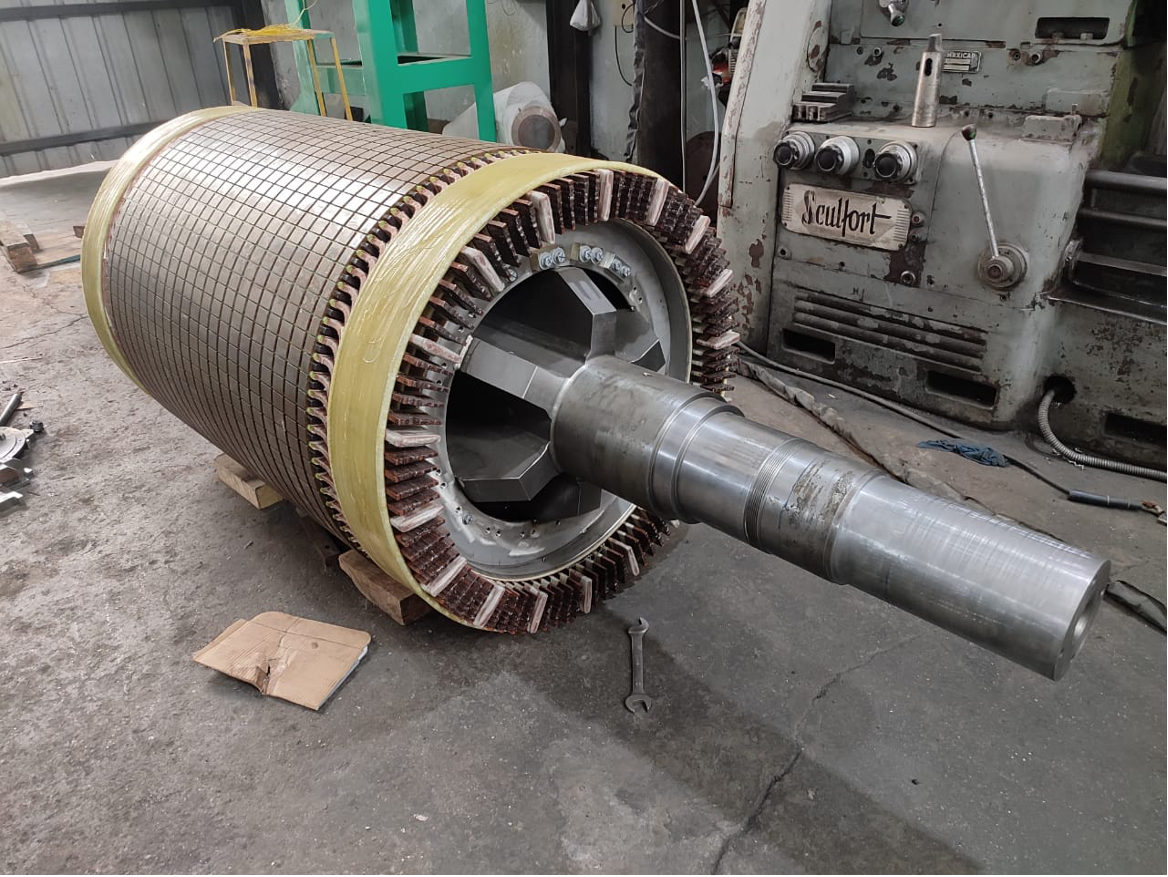

Generator Rotor Shaft Rectification

Supertech Generator Rotor Shaft Rectification Service in Pune. Wind Power is one of the power sources of India. Working on the fields of windmills is another great and difficult task for respective services as the parts are heavy, costly, and précised also. Generator Rotor Shaft is one of the important parts of a windmill assembly. Calculations of all operations are very specific on that height. But when the rotor shaft is damaged or slips out from the original dimensions, accidents or some other problems may cause. That’s where we come in.

We at Supertech developed a process called Rotor Shaft Rectification. First, we inspect the rotor damaged areas. Sometimes the shaft diameters are damaged due to the rotor and stator clashing in the generator body. Sometimes the rotor does not appear in the drawing tolerance limits. We rectify all these problems and deliver the shaft just as new. All processes are completed and maintained under International Standards.

Instead of scraping the whole shaft body, the rotor shaft body can be used again and again because of this process. Generator Rotor Shaft Rectification Service in Pune.

Generator Rotor Shaft Rectification Service in Pune

Generator rotor shaft rectification is an important service for the power generation industry, and Supertech is a leading provider of this Generator Rotor Shaft Rectification Service in Pune. Our skilled technicians and advanced equipment allow us to perform precise and efficient repairs on generator rotor shafts. Improving their performance and extending their lifespan.

The generator rotor shaft is a critical component in a generator. As it supports the rotor and maintains the alignment of the rotor with the stator. Over time, the rotor shaft can become worn or damaged. Which can lead to vibration, reduced efficiency, and even failure of the generator. Rectification of the rotor shaft involves a variety of processes designed to restore the shaft to its original specifications and improve its performance.

At Supertech, we use a variety of inspection techniques to determine the condition of the rotor shaft and identify any defects or wear patterns. This may include visual inspection. As well as non-destructive testing techniques such as magnetic particle inspection or ultrasonic testing. Once the condition of the rotor shaft has been determined. We can begin the repair process. Generator Rotor Shaft Rectification Service in Pune.

One common repair process for generator rotor shafts is grinding. Grinding involves removing a small amount of material from the surface of the shaft to improve its finish and alignment. This process can be performed manually or with the use of computer-controlled grinding machines. The amount of material removed depends on the extent of the wear or damage. As well as the desired specifications for the finished shaft.

In addition to grinding, we also use polishing to further improve the surface finish and reduce friction. This process involves using an abrasive material to smooth the surface of the shaft. We may also use welding or machining for more extensive repairs. Depending on the extent of the damage.

Once the repair process is complete, we reassemble the generator rotor shaft and perform dynamic balancing. Ensure it meets the necessary specifications for performance and alignment. This testing is critical to ensuring that the generator can operate efficiently and safely.

At Supertech, we understand the importance of timely and efficient generator rotor shaft rectification. Downtime can be costly for power generation companies. For our clients’ benefit, we strive to reduce downtime and maximize uptime by offering prompt, dependable service. Our skilled technicians have years of experience in this specialized field.

In addition to generator rotor shaft rectification, Supertech also provides a range of other services related to power generation equipment, including inspection, maintenance, and repair. Industrial and commercial buildings, and other facilities. Whether a client requires basic upkeep or intricate repairs. Our aim is to offer complete solutions that cater to their specific needs.